There’s an innovative solution to conventional labor-intensive, time-consuming processes in ICF construction and it’s only produced by Helix St

Helix Steel Explains the Most-Highly Sought-After Product in the Concrete Reinforcement Field

You know rebar. Everyone does. It’s that heavy, awkward, rusty material that eats up your construction schedule and causes problems.

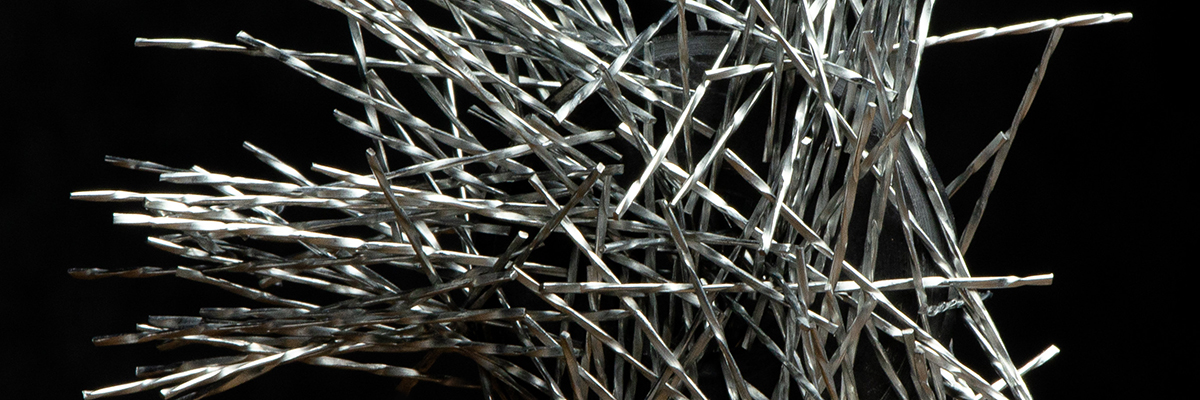

Not everyone knows about the product that in many cases has made rebar obsolete. It’s Helix® Micro Rebar™ by Helix Steel, a Michigan-based innovation-centered business with a mission to make the construction world work better. Helix® Micro Rebar™ is the only ISO-certified concrete micro-reinforcement that stops cracks before they even start. The proactive all-steel micro-sized solution is better than standard rebar in almost every way, and since its inception approximately 20 years ago more and more industry leaders are understanding – and relying on – its differences.

Helix® Micro Rebar™ and Its Small Start

Helix Steel launched Helix® Micro Rebar™ in 2003 after a study through the University of Michigan which proved that a small, twisted piece of metal, combined with thousands of others, resulted in far better resiliency, ductility and elasticity to concrete structures than any other metal or plastic concrete reinforcement.

The results from the university study were astounding, and industry leaders began to take notice of this tiny solution. Helix Steel founder and president Luke Pinkerton soon realized that his business’s small way of thinking was quickly making big differences. And so the “Helix® Micro Rebar™ Age” was launched.

How Does Helix® Micro Rebar™ Work?

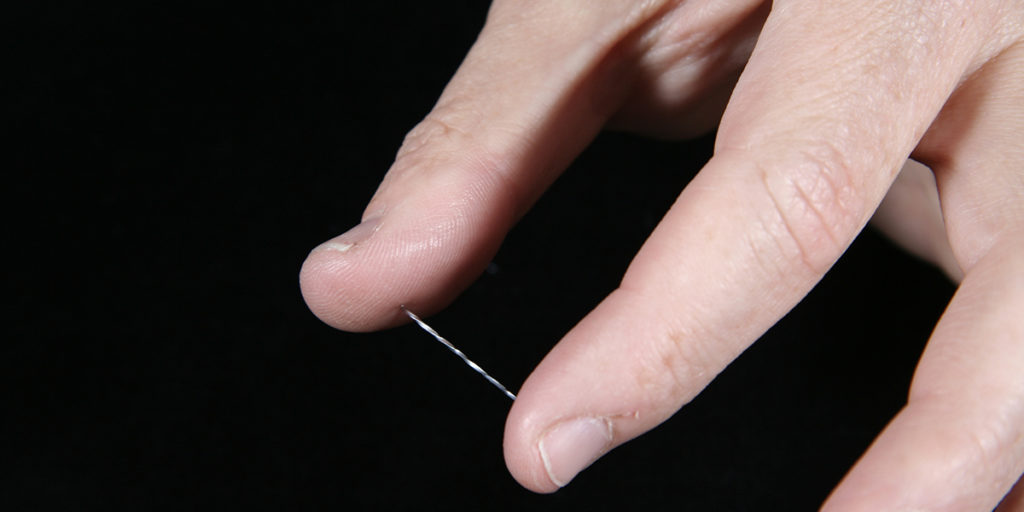

Helix® Micro Rebar™ is crafted in coated steel, and while it is only one inch in length, it’s twisted and combined with thousands of other pieces in concrete.

Since each piece of Helix® Micro Rebar™ is twisted, it works similarly to the way a screw does; when a screw is drilled into wood it grips the wood and holds two pieces together, while resisting forces that want to pull it apart. Pulling out a piece of Helix® Micro Rebar™ is practically impossible.

Once fully cured, the Helix® Micro Rebar™-filled concrete resists separation forces – cracking – resulting in a massive increase in concrete’s shear strength, durability and ductility while providing industry-leading pre-crack capabilities. Unlike fibers and rebar Helix® Micro Rebar™ has never failed in real-world applications.

The patented product has been proven as a superior concrete reinforcement in a wide range of applications, including concrete slabs, walls, foundations, roads, precast tanks, tunnel linings and more.

What’s the Big Deal with All-Steel Helix® Micro Rebar™?

Along with shear strength, durability and ductility, there are other benefits for architects, general contractors, ICF builders, developers and many more. There are actually hundreds of reasons to choose Helix® Micro Rebar™, but here are some of our customers’ favorites:

- By not having to install rebar, you will save a full day of construction for every 10,000 square feet of slab you’re creating.

- You can reduce the size of your construction crew, and minimize your onsite storage.

- Helix® Micro Rebar™ will remove rebar’s risk – the heavy lifting, rusty metal and back-breaking labor.

- Contractors will have time to secure more projects – a more-reliable product, with shorter timelines, safer job sites and lower installation costs. This allows general contractors to be more competitive and attractive to developers.

- Lastly, it helps to create a world that is free from concrete cracks, and reduces tenant/owner complaints. Helix® Micro Rebar™ is your best crack-free solution.

How is Helix® Micro Rebar™ Different from Fiber Concrete Reinforcement?

Now that you know more about Helix® Micro Rebar™, let’s take a look at how it differs from fiber. Most importantly, understand that while Helix® Micro Rebar™ stops cracks before they start, fibers only start working once concrete has already cracked – similar to standard rebar.

Helix® Micro Rebar™ creates flexural strength (MOR) and consistency at doses lower than any fiber. Since plastic fibers are softer than concrete, they act like voids prior to cracking. Even older steel fibers have drawbacks – they rely on friction to provide resistance.

In a study, Helix® Micro Rebar™ at (25 lb/yd) was compared to plain concrete and a standard steel fiber with deformed ends at (60 lb/yd). The results show the advantages of Helix® Micro Rebar™ in pre-crack tensile performance even when applied at a lower dosage. Additional independent studies have shown that plastic, synthetic and steel fibers can improve post-crack performance, but they do not affect pre-crack performance.

ii. Element Labs Report #ESP016080P, March 27, 2014

iii. Carnovale, David, “Behaviour and Analysis of Steel and Macro-synthetic Fibre Reinforced Concrete Subjected to Reversed Cyclic Loading”, University of Toronto, 2013, pp 84-86.

It’s Time to Rethink Rebar and Refocus on Rewarding Results

Helix® Micro Rebar™ is here to stay, not only because of its 0% failure rate, but also because its many other benefits that far outweigh the current standards.

Learn more about Helix® Micro Rebar™, how it works and the many ways that it can work hard for your next project by contacting the Helix SteelⓇ Sales & Technical Team at 734-322-2114 x3 or sales@helixsteel.com.

We look forward to sharing more about the power of Helix® Micro Rebar™ with you soon.

More News

Building Better Homes Starts with ICF and Helix Micro Rebar

The Better Way to Build in Every Direction

Whether you’re building below-grade or above-grade, the tiny twisted concrete reinforcement known as Helix Micro Rebar is taking the construction world in new directions

Is Your Business Still Living in the Rebar Age?

If you’re in the construction industry to improve buildings, revolutionize processes and work smarter, it may be time to rethink your concrete reinforcement.