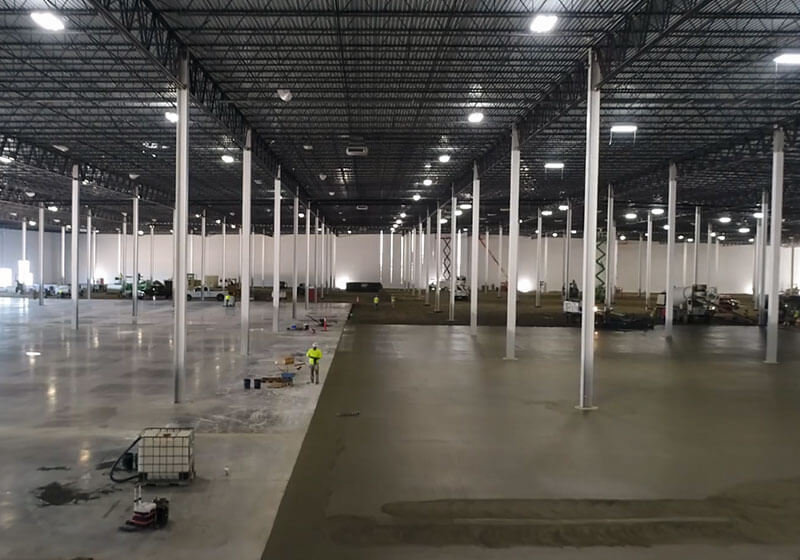

Ashley Capital has become one of the largest privately-held real estate investment companies in the United States. They recently added the Livonia West Commerce Center to their portfolio of 23+ million sq. ft.

About the Course

This RCEP-accredited course provides insight into how global warming is impacting the concrete industry. The capabilities of current metrics to assess global warming will be discussed, as well as the essential tenets of sustainable construction and the frameworks used to assess project carbon footprints. This course offers a study of material life cycle assessment and energy use, as well as best practices and procedural benchmarks to analyze and refine findings pertinent to industrial ecology. Finally, strategies for minimizing global warming impact will be introduced and solutions will be analyzed.

This course is intended for industry practitioners, design professionals, and experts interested in promoting and pursuing sustainable engineering and construction principles, as well as for anyone learning about how building practices are increasingly moving towards becoming environmentally-friendly. This course will also provide knowledge about industry expectations and future trends in the concrete industry.

You will receive an official Certificate of Completion after the completion of this course.

Prerequisite Knowledge

Basic knowledge of the concrete industry, construction engineering, and sustainable practices

Learning Objectives

- Understand and communicate the internal and external factors driving sustainable concrete practices, and what sustainability means in industry.

- Identify and assess the key metrics used to study global warming and its impact in the concrete industry.

- Communicate the role of carbon footprint in projects that use concrete, as well as energy costs and material life cycles in contributing to overall emissions, and how more sustainable practices can reduce emissions and streamline life/use cycles.

- Describe and critique solutions and strategies for minimizing emissions and global warming, and how to best integrate these into practices associated with concrete.

Presented By:

Luke Pinkerton

President & Chief Technology Officer, Helix Steel

Luke Pinkerton, PE (ME) is the President, Chief Technology Officer and founder of Helix Steel. He has a BS in engineering physics from Hope College, an MS in structural engineering from the University of Michigan, and an MBA from Georgia Institute of Technology.

About Helix Steel

Helix Steel is an innovative business based in Michigan that manufacturers and distributes the proprietary Helix® Micro Rebar® concrete reinforcement. The one-inch-long twisted steel pieces are mixed with concrete to create a long-lasting bond, preventing cracks before they even start, and are code-approved in many applications from warehouse slabs and highway bridges to tilt-up panels and ICF.

Proactive Concrete Reinforcement Technology

Saves You Time

Every 10,000 sq. ft. of rebar replaced with Micro Rebar® saves one full day of construction.

Saves You Money

Using Micro Rebar® allows contractors to simplify operations, dramatically reducing project costs.

A Superior Product

When compared to rebar, Helix® Micro Rebar® can increase fatigue resistance by up to 300%, and flexural strength by up to 33%.

Featured Projects

Pier 57 Ferris Wheel

Pier 57 is a Seattle waterfront location favored by tourists and locals. It was lengthened to construct a 156 ft diameter Ferris wheel which opened in 2012. Helix® Micro Rebar™ reinforcement was incorporated into the project design to fully replace the #6 rebar cages inside 53 piles.

Pulaski Egg Farm

Rose Acre Farms offers commodity eggs, specialty eggs including cage-free varieties, liquid eggs, dried eggs, and egg protein powder.

Indigo Green

The Villages of Indigo Green on St. Maarten are located in one of the most desirable destinations of the Caribbean.

MARS Pavilion

Helix® Micro Rebar™ reinforcement allows architects to design structures that are not rectangular and provides a reinforcement solution for technologies such as 3D concrete printing.