There’s an innovative solution to conventional labor-intensive, time-consuming processes in ICF construction and it’s only produced by Helix St

If you work with concrete, you are very familiar with the frustrations of using rebar. Who knew that a simple metal rod used for 100+ years could still be causing so much frustration in an industry that otherwise is innovating faster than ever before?

Whether you’re a contractor, laborer, ICF home builder, precast company, or developer, there has never been a better time to rethink your concrete reinforcement and consider Helix Micro Rebar.

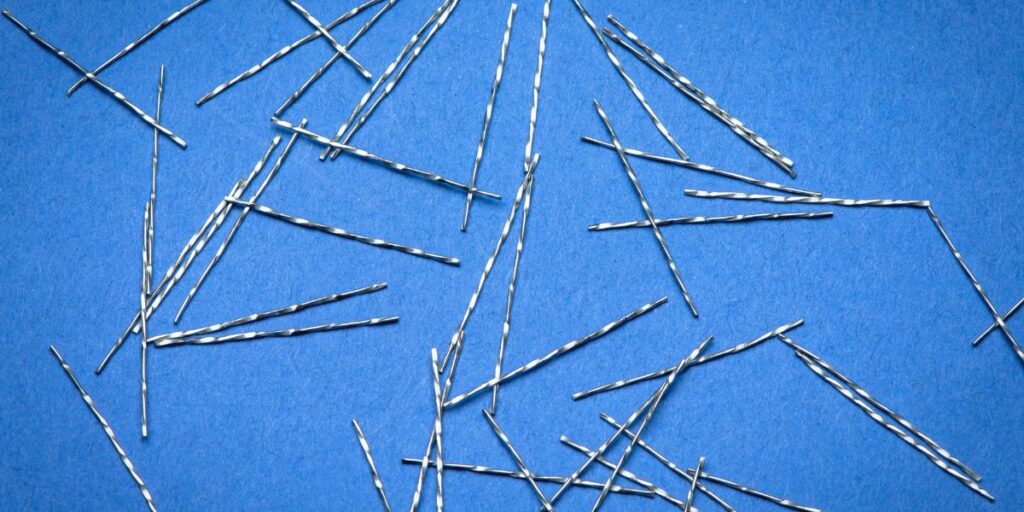

Helix Micro Rebar is a small, one-inch steel rod twisted and combined with concrete to create a superior concrete product. It isn’t even that “new”, but it might be new to you. It has been used over the past 20 years in more than 100 million square feet of slabs and more than 20,000 vertical structures. Brands that trust Helix Micro Rebar include Amazon, FedEx, General Motors and Hilton.

And it is everything you want a concrete reinforcement to be.

But how does it compare to rebar?

Why drop everything you know about concrete reinforcement for an alternative?

We’re glad you asked…

Helix Micro Rebar Takes Less Effort Than Rebar

Rebar needs to be ordered far in advance and placed in large storage yard until needed. Once needed, they are picked up by cranes and hefted to the worksite where each piece of rebar is picked up by your crew, lifted into place, then tied down by teams of laborers. When it comes to installation, rebar is always frustrating, dirty, rusty and often involves placement mistakes.

Helix Micro Rebar is the opposite in a lot of ways. This product is mixed with concrete before it is placed, and involves very few laborers – and mostly just on pour day. These jobsites are simple, clean and safe, and have Helix Steel engineers available to help at every step of the way – reducing effort for your team.

Helix Micro Rebar Takes Less Time Than Rebar

If you’re working on a warehouse concrete project, you may need to set aside weeks to install the rebar. Planning, managing crews and installing all take time and effort.

If developers want a faster return on their investment, or if contractors need to jump onto another project sooner, there is no better option than Helix Micro Rebar.

In many slab applications, every 10,000 sq. ft. of rebar replaced with Micro Rebar saves one full day of construction. Since Helix Micro Rebar is mixed in with concrete and poured into its final destination, almost all of the time scheduled for rebar installation is saved. You will also save time during the pour itself. Cement mixers can be driven directly onto the warehouse floor and pour at the location where the concrete is needed. This alone can improve your pour rate by up to 20%.

Helix Micro Rebar is Safer Than Rebar

Just thinking about rusty rebar gives us tetanus. It is heavy, awkward and a trip hazard on every jobsite. How many times have your crew members tripped on rebar? Once is too many.

Helix Micro Rebar is delivered in easy-to-handle cardboard boxes that greatly minimize contact with the reinforcement. With significantly smaller crews, fewer tripping hazards and less equipment needed, jobsites with Helix Micro Rebar have been proven to be safer.

Helix Micro Rebar Has Minimized Post-Construction Risk

One of the biggest struggles with using concrete is preventing crack formation. We are led to believe that rebar “should” stop cracks from forming, but in many cases, it’s only used to “reduce” the number and size of cracks. Standard concrete reinforcement is not as perfect as its popularity portrays.

Helix Micro Rebar is twisted to help give concrete five times the tensile strength compared to rebar-reinforced concrete and up to a 33% increase in modulus of rupture (flexural strength), which maximizes the structural durability against corrosion, earthquakes, water penetration and blasts.

Helix Micro Rebar also has a specialized coating that resists rust three times longer than conventional uncoated steel reinforcement. This helps to prevent cracks at the micro level and resists failure.

Helix Micro Rebar Has Lower Costs Than Rebar

Made of steel that’s hot-rolled into form, rebar can be slightly cheaper than Helix Micro Rebar when comparing direct material costs.

But when you factor in your reduction in labor costs, time savings, safety improvements and customer satisfaction, the difference is clear. Your project’s overall savings is significant, as is the higher-quality concrete product.

Submit Your Project

We are here to help make it easy to learn about the alternative to rebar and helping to make your job more efficient.

Send us some basic details about your project and we will help you to design a solution that works for you in just a couple of days. Submit Your Project Here

Learn more about Helix Micro Rebar and the many ways that it can work hard for your next project by contacting Helix Steel’s Sales & Technical Team at 734-322-2114 x3 or sales@helixsteel.com.

We look forward to sharing more about the power of Helix Micro Rebar soon.

More News

Building Better Homes Starts with ICF and Helix Micro Rebar

The Better Way to Build in Every Direction

Whether you’re building below-grade or above-grade, the tiny twisted concrete reinforcement known as Helix Micro Rebar is taking the construction world in new directions

Is Your Business Still Living in the Rebar Age?

If you’re in the construction industry to improve buildings, revolutionize processes and work smarter, it may be time to rethink your concrete reinforcement.